Euromonitor International has predicted that sales of baked goods in the People’s Republic of China will increase 22.5% by 2021. Domestic wheat is less than optimal in flour production and quality for these baked goods, so imports are needed. USDA Foreign Agricultural Service cooperator U.S. Wheat Associates (USW) is using Market Access Program (MAP) and Foreign Market Development (FMD) program funds to meet that demand by helping the Chinese baking industry tackle technical challenges to produce world class baked goods using imported U.S. wheat.

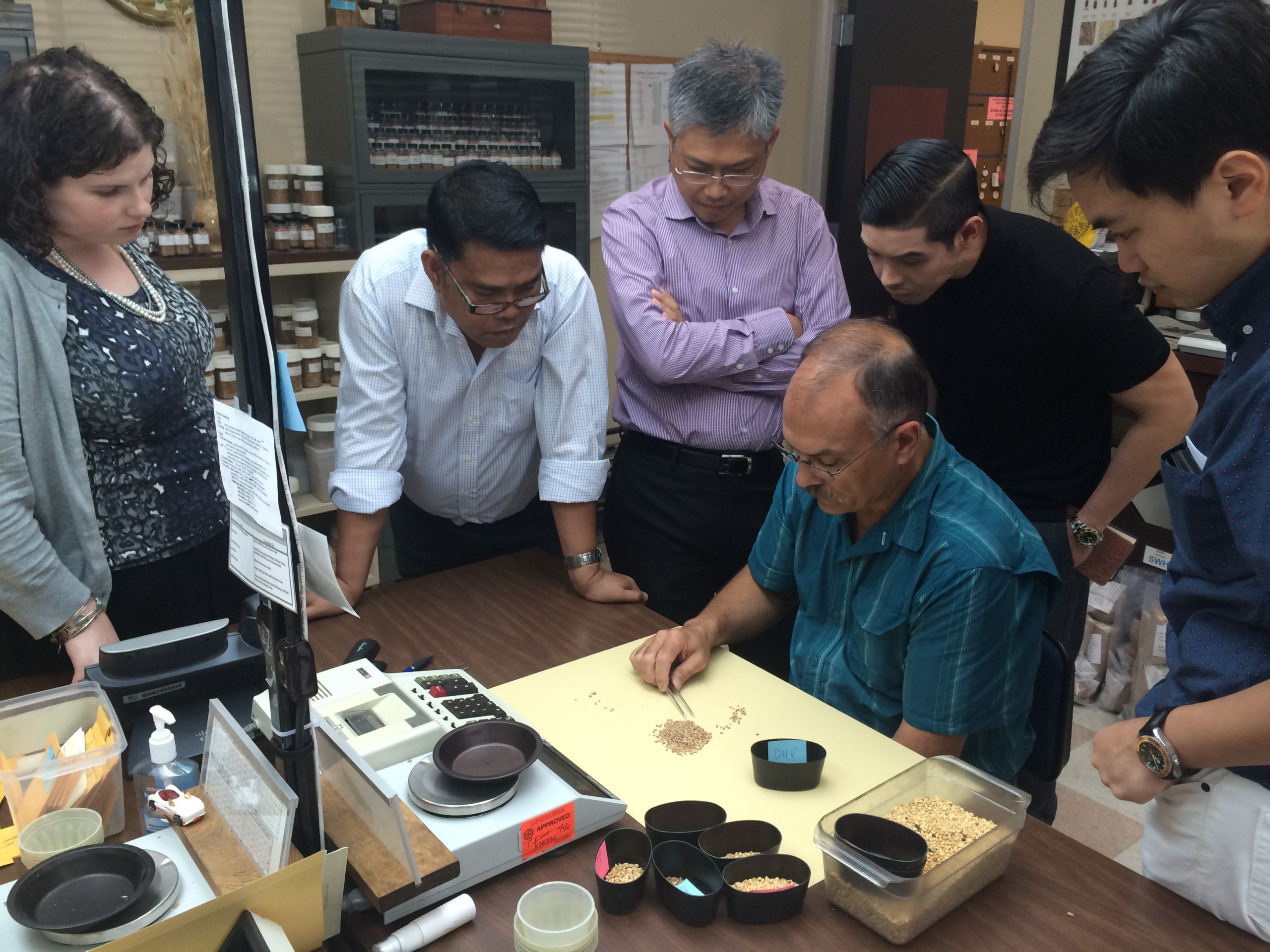

USW applied FMD funds to hire Dr. Ting Liu in September 2016 as Technical Specialist to bolster USW’s technical ability to demonstrate U.S. wheat performance qualities for new baked goods. One of Dr. Liu’s first projects, supported by MAP funds, was to help the Sino American Baking School (SABS) in Guangdong Province offer consultation to baking companies that have some experience using flour made from U.S. wheat. The long-term goal is to help them expand new specialty items such as sourdough, frozen dough and whole grain products. In marketing year 2016/17, three Chinese companies requested the technical assistance from senior specialists currently teaching at, or recently retired from, SABS. USW and SABS are strongly associated with excellent instruction and product development, so USW’s support is also helping build stronger reputations for both the school and for U.S. wheat.

Growing demand for baked goods and interest in healthy, whole grain products represents good opportunity to increase Chinese demand specifically for high-protein U.S. hard red spring (HRS) wheat. In May 2017, Dr. Liu represented USW at the 2017 Sino-Foreign Whole Grain Industry Development Experts Forum in Shanghai. Joining 22 experts in food processing, nutrition and health, financial investment, policy and marketing, Dr. Liu actively participated in the forum as one of 10 industry guest speakers. Drawing from USW’s activities in several other countries, Dr. Liu’s presentation focused “International Whole Grain Development,” which provided guidelines and references to the development of whole grains products in China.

China’s U.S. wheat imports can swing up or down with government policy decisions. However, total U.S. import volume doubled in 2016/17 to more than 1.6 million metric tons (MMT) compared to almost 880,000 MT in 2015/16. A closer look shows China’s annual import of HRS wheat grown in Minnesota, North Dakota, Montana and South Dakota has steadily increased the past five years from 475,000 MT in 2012/13 to more than 1.1 MMT in 2016/17. That is the second highest volume of HRS imports in the world that year.