Name: Shin Hak “David” Oh

Title: Food/Bakery Technologist

Office: USW North Asia Region, Seoul Office

Providing Service to: South Korea

The roots of Shin Hak “David” Oh’s food technology career were literally and figuratively fermented in his childhood home in Seoul, South Korea.

The Korean art of making “kimchi” fascinated Oh as a child. Everyone in the family pitched in to salt the vegetables and mix them with chili powder, garlic, ginger, red pepper, sugar, and fish sauce that fermented in earthenware jars, often buried in the ground. It is an ancient process that was first practiced to provide nutritious food through the cold winters and continues to represent the cultural soul of Korea today.

In the arms of his father, a clothing wholesaler, and mother, a homemaker, in 1979.

“I developed a natural interest in fermented food and microorganisms as I helped make our kimchi,” Oh said. “That interest stayed with me as a young person, so I chose to study food and biotechnology at Korea University in Seoul and earned a bachelor’s degree in 2003.”

Now armed with the scientific facts behind how kimchi fermentation removes harmful bacteria and enriches gut-healthy lactobacillus bacteria, Oh decided to pursue a graduate degree at the respected Seoul National University. His work focused on improving food safety and included research on a new regulatory system for inhibiting Salmonella and other pathogens in food. Along the way through university, Oh found time for other important life experiences, including marriage to his wife, Jiae.

Oh’s graduate work at Seoul National University focused on developing methods to inhibit Salmonella and other pathogens in food.

Celebrating Oh’s graduation with a master’s degree in food and biotechnology in 2005 with his wife, Jiae, in his university laboratory.

Professional Success

Oh’s route from food microbiology studies to his current position as Food/Bakery Technologist with U.S. Wheat Associates (USW) started in 2005 with his first professional job at SPC Group, the largest bakery company in Korea. As a food safety specialist for two years, Oh helped SPC comply with Korean government food and consumer safety regulations in bakery production, storage, and packaging. He also served on a team that implemented Hazard Analysis & Critical Control Points (HACCP) food safety management systems.

Based on the advice of SPC’s food safety center director, Oh successfully pursued a research and development position with the company.

“In that job, I developed several improvers to enhance the quality of pan breads, sweet buns, and frozen dough products,” Oh noted. “I also developed a special ‘sugar-free pan bread,’ which is still sold in some of SPC’s Paris Baguette retail bakeries in Korea.”

His work at SPC, as well as additional hands-on training at AIB International’s “Baking Science and Technology” and “Food Safety and Hygiene” courses, caught the attention of USW Country Director C.Y. Kang. He was looking for candidates to fill a technical support position to expand U.S. wheat export market development in the Korean market.

Oh completed baking technology and food safety courses at AIB International in Manhattan, Kansas, while working at SPC Group in Seoul, South Korea.

At SPC, Oh developed a sugar-free pan bread product. In 2013, he was on the factory line as the product was packaged for distribution to SPC’s retail stores.

“David’s great work over eight years at our country’s biggest and most popular commercial and retail bakery was quite impressive,” Kang said. “It also did not take long to see that he is very friendly and kind to everyone. We agreed he would be a great fit with U.S. Wheat Associates and very helpful to our customers in flour milling, baking, and wheat food processing.”

“I went for the position with USW without hesitation, partly because most of the high-quality flour SPC used for bread products was milled from imported U.S. wheat classes,” Oh said. “I had grown passionate about baking at SPC, and I thought the position would also help me expand my knowledge about producing biscuits (cookies), noodles, and other wheat foods.”

Seeking Broader Knowledge at USW

Oh said his expectations were more than met after he started with USW at the beginning of 2015.

“There are many milling, baking, and production experts across our offices and we often help and learn from each other,” he said. “I am a hands-on person, and a technical sales position like this gives me the opportunity to share all of our experience and skills with our customers to help them improve their processes, customer satisfaction, and income using flour made from U.S. wheat.”

That effort takes many forms. One recent example is a seminar held in Korea for bakers from commercial operations in the Philippines.

“Our market is fairly mature with sophisticated processes and very high standards for ingredient quality,” Kang said. “Our USW colleagues wanted to help introduce these processes and new products to customers in the Philippines, so David and I arranged sessions in Seoul at the Korean Baking School and visits to Korean companies for the bakers.”

In addition, Oh has now conducted several baking, biscuit, and noodle production courses at the Korean Baking School in Seoul and, in cooperation with the Wheat Marketing Center (WMC) in Portland, Ore., for technical managers from flour mills and processors. Oh discusses and demonstrates blended flour from U.S. wheat classes to the participants, who then test the blends to identify optimal formulations for their commercial products. Drawing from his research experience at SPC, bakery applications developed at USW courses, and the Korean Baking School, Oh has introduced new products, including whole wheat baked goods made with U.S. wheat flour, in four seminars to approximately 300 commercial bakers.

At a Whole Wheat Flour Seminar hosted by Korean flour milling and commercial baking organizations in 2018, Oh presented ideal U.S. wheat flour formulations for bakery applications developed by USW and Korean customers at several activities.

USW is unique in having strong technical expertise available to customers in their mills and production facilities. This is a key part of Oh’s work.

“I am excited to be part of Korea’s thriving wheat food industry. I enjoy visiting our customers and helping them understand the specific milling and functional characteristics of the U.S. wheat classes available to them and how to apply that knowledge to get the most value from their own mills and end-product processes,” Oh explained. “If they have concerns or need troubleshooting, we can be there with them, and that builds a stronger partnership for the future.”

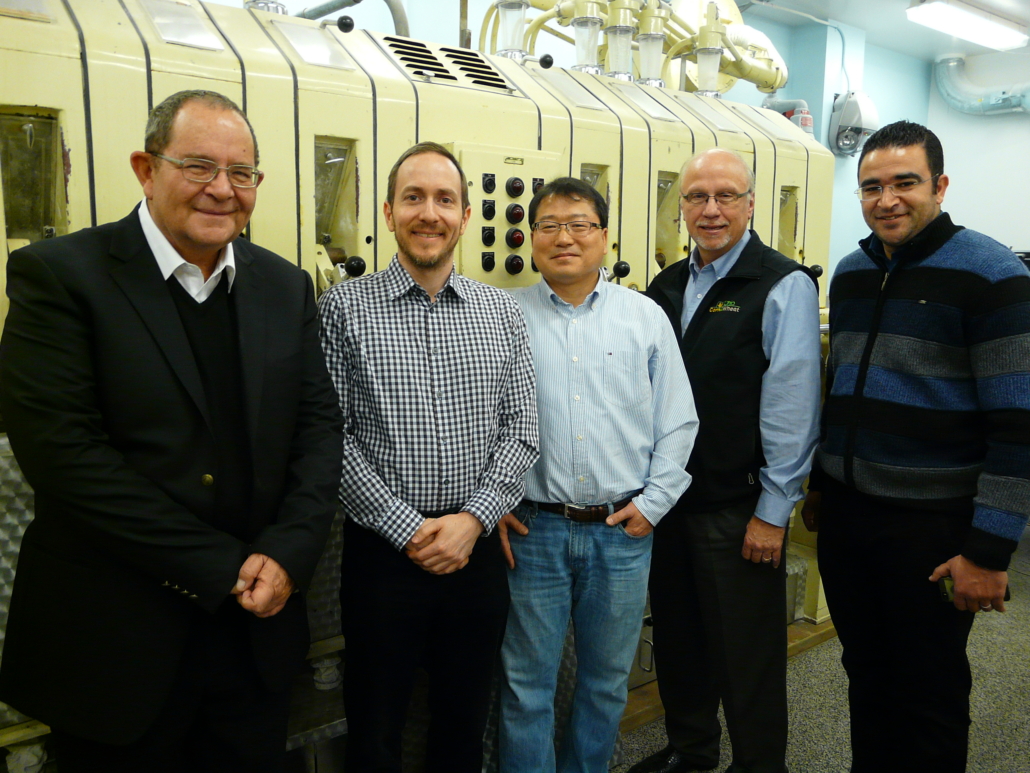

In cooperation with the Wheat Marketing Center, Portland, Ore., Oh (fourth from right) helped plan and conduct a Korea Baking Product Development course in 2019.

Sharing Knowledge

Oh’s individual efforts in the baking laboratory also come into play as he works to share the results of testing with Korean bakery customers. In 2017 at the Korean Baking School, Oh tested different blends of hard red spring (HRS) and hard red winter (HRW) flour to make sweet buns and blends of HRW and soft white flour to make Korean-style baguettes. He then provided data on the best formulations to customers.

Oh in the laboratory at the Korean Baking School, testing formulations of testing blends of HRW and SW flour for Korean-style baguettes and HRS and HRW flour for sweet buns in 2017.

Differentiating the performance of U.S. wheat in Korean noodles, however, has presented a unique challenge for Oh and for the U.S. farmers he represents.

“Compared to Australia, specifically, there is no single U.S. wheat class with optimal qualities for Korean style noodles,” he said. “So, we have approached that challenge by holding ‘Noodle Flour Blending and Quality’ seminars at the Wheat Marketing Center for as many industry participants as possible. Based on their reports about the seminars, our information has given them reasons to consider blending flour from U.S. wheat. Now, flour from U.S. soft white wheat makes up a 20 percent share of the Korean noodle market.”

An Excellent Balance

Undoubtedly, the level of trust Oh is developing across the diverse Korean industry is boosted by his professional training and experience.

“David has in-depth knowledge on the key facts of wheat flour that are very critical to end-product quality,” said the research and development manager from Korea’s largest instant noodle manufacturer. “I assume that comes from his graduate degree work and experience at SPC Group. He has provided all the results from short courses, seminars, and testing to us and helps us apply that information and U.S. wheat flour formulations effectively in our operation. We very much appreciate his efforts.”

It is said that the five flavors of kimchi (sour, bitter, salty, sweet, and spicy) and their balance permeates every facet of Korean life. Oh finds a similar balance between work and pleasure. His colleagues appreciate that in Oh, as those who have seen an exuberant rendition of the dance moves from K-Pop star PSY’s “Gangnam Style” or seen the pride he takes in his family can attest.

C.Y. Kang put it best: “David is a great asset to the entire USW organization.”

By Steve Mercer, USW Vice President of Communications

Editor’s Note: This is the sixth in a series of posts profiling U.S. Wheat Associates (USW) technical experts in flour milling and wheat foods production. USW Vice President of Global Technical Services Mark Fowler says technical support to overseas customers is an essential part of export market development for U.S. wheat. “Technical support adds differential value to the reliable supply of U.S. wheat,” Fowler says. “Our customers must constantly improve their products in an increasingly competitive environment. We can help them compete by demonstrating the advantages of using the right U.S. wheat class or blend of classes to produce the wide variety of wheat-based foods the world’s consumers demand.”

Header Photo Caption: David Oh conducting a fresh noodle evaluation using U.S. hard white wheat flour blended with Australian Standard White flour at Daehan Flour Mills in Incheon, South Korea.

Meet the other USW Technical Experts in this blog series:

Ting Liu – Opening Doors in a Naturally Winning Way

Tarik Gahi – ‘For a Piece of Bread, Son’

Gerry Mendoza – Born to Teach and Share His Love for Baking

Marcelo Mitre – A Love of Food and Technology that Bakes in Value and Loyalty

Peter Lloyd – International Man of Milling

Ivan Goh – An Energetic Individual Born to the Food Industry

Adrian Redondo – Inspired to Help by Hard Work and a Hero

Andrés Saturno – A Family Legacy of Milling Innovation

Wei-lin Chou – Finding Harmony in the Wheat Industry