BUYING TERMS

C&F (Cost and Freight). Seller provides the cargo, covers the loading costs and charters the ocean vessel for a specific destination. The buyer must pay for insurance and for discharge of the grain from the vessel. Buyer specifies shipment period.

CIF (Cost, Insurance, Freight). Seller provides the cargo, covers the loading costs and charters the ocean vessel, plus insures the cargo until it reaches its destination. Seller determines the final loaded quantity within the contract quantity tolerance; the buyer pays for discharge. Buyer specifies shipment period.

FOB (Free on Board). Seller is responsible for placing grain at the end of the loading spout. Buyer is responsible for providing the ocean vessel, and for all other costs after the grain is delivered on board, including stowing and trimming the cargo in the holds. Buyer determines the final loaded quantity within the contract quantity tolerance. Buyers specify delivery period.

Agricultural Marketing Service (AMS).

An agency within the USDA, AMS administers programs that create domestic and international marketing opportunities for U.S. producers of food, fiber, and specialty crops. AMS also provides farmers, handlers, processors, exporters, and international buyers with information and tools that accurately and consistently describe the quality and quantity of the grain and commodities being bought and sold by:

- Managing the national inspection and weighing system, a unique network of Federal, State, and private laboratories that provide impartial, user fee funded official inspection and weighing services.

- Protecting the integrity of the official inspection system and the market at large to ensure markets for grain and related products are fair, transparent, and free from deceptive and fraudulent practices.

- Providing the market with terms and methods for quality assessments. The Official U.S. Standards for Grain are used each and every day by sellers and buyers around the world to communicate the type and quality of grain bought and sold. Our standard testing methodologies accurately and consistently measure grain quality.

- Providing traditional and innovative inspection and weighing services to the traditional bulk and specialty commodity markets.

- Providing international services and outreach programs that keep America’s grain flowing to our international customers.

Federal Grain Inspection Service (FGIS).

FGIS was created by Congress in 1976 to manage the national grain inspection system, which was initially established in 1916, and to institute a national grain weighing program. Today, as a program within USDA’s AMS, FGIS facilitates the marketing of U.S. grain and related products by establishing standards for quality assessments, regulating handling practices, and managing a network of Federal, State, and private laboratories that provide impartial official inspection and weighing services.

Under the United States Grain Standards Act (USGSA) and the Agricultural Marketing Act of 1946 (AMA), FGIS:

- Establishes and maintains official U.S. grain standards for barley, canola, corn, flaxseed, oats, rye, sorghum, soybeans, sunflower seed, triticale, wheat, mixed grain, rice and pulses.

- Inspects and weighs grain and related products for domestic and export trade

- Establishes methods and procedures, and approves equipment for the official inspection and weighing of grain.

- Supervises the official grain inspection and weighing system. The official system is a network of FGIS field offices, and State and private grain inspection and weighing agencies across the nation that are authorized by FGIS to provide official inspection and weighing services.

- Provides international services and outreach programs and protects the integrity of the official inspection system and the market at large to ensure markets for grain and related products are fair and transparent.

Letter of Credit. The most common form of payment for U.S. wheat, in which the buyer’s bank first establishes a letter of credit in favor of the seller. When the grain is shipped and documentation is presented, the seller’s bank makes payment to the seller, then the buyer’s bank makes payment to the seller’s bank. A letter of credit greatly reduces commercial risk for the seller, but involves higher bank service charges.

WHEAT GRADE DATA

Wheat Grades reflect the physical condition of a sample and may indicate its general suitability for milling. The U.S. grade for a sample is determined by measurement of such factors as test weight, damaged kernels, foreign material, shrunken and broken kernels and wheat of other classes and contrasting classes. All numeric factors other than test weight are reported as a percentage by weight of the sample. Grade determining factors include:

Test Weight is a measure of density in pounds per bushel (lb/bu) or kilograms per hectoliter (kg/hl). Test weight may indicate potential milling yield and the general condition of the sample. Problems during the growing season or at harvest often can reduce test weight.

Damaged Kernels show signs of disease, insect activity, frost or sprouting and may adversely affect milling and flour quality.

Foreign Material is any material other than wheat that remains after dockage is removed. Because foreign material is not easily removed, it may have an adverse effect onadversely affect milling and flour quality.

Shrunken and Broken kernels have a shrunken or shriveled appearance or were broken in handling that may reduce milling yield.

Vitreous Kernels in HRS wheat are uniformly dark and have no spots that appear chalky or soft. In durum, vitreous kernels have a glassy and translucent appearance without any spots that appear chalky. Vitreous kernel is the percentage handpicked from a 15 gram (g) clean wheat sub-sample.

Total Defects is the sum of damaged kernels, foreign material and shrunken and broken kernels.

Wheat of Other Classes and Wheat of Contrasting Classes. Wheat classes are specific to end use and if too much of a wheat of another class is found the grade is lowered. Amounts allowed are much lower for contrasting wheat classes because the end-use is different and the negative influence on end-use performance is greater.

Stones and other non-Wheat Material. Limits are placed on non-wheat material such as stones, weed seeds, animal filth and any other unknown foreign substances

WHEAT NON-GRADE DATA

Dockage is the percentage by weight of material removed from a sample by the Carter Dockage Tester and does not influence the numerical grade. Being easy to remove, dockage should not affect milling quality but may have other economic effects for buyers. Official USDA procedures.

Moisture content is the percentage of water by weight in a sample and is an important indicator of profitability in milling. Flour millers add water to adjust wheat moisture to a standard level before milling. Lower wheat moisture allows more water to be added, increasing the weight of grain to be milled at virtually no cost. Moisture content is also an indicator of grain storability as wheat and flour with low moisture are more stable during storage. Because moisture can be readily added to or removed from a sample, other analysis results should be mathematically converted to a standard moisture basis (mb), such as 14%, 12% or dry matter, so test results can be consistently evaluated. Protein content is the percentage of protein by weight in a sample. Because there is no rapid way to measure wheat protein quality, protein quantity is used in trade and by millers as an indicator of the suitability of wheat or flour for various products and is an important factor in determining wheat value. High protein is usually desired for products such as pan breads, pasta, buns and frozen yeast-raised products. Low protein is usually desired for products such as snacks or cakes.

Ash content is the percentage of minerals by weight in wheat or flour. In wheat, ash is primarily concentrated in the bran and is an indication of the expected flour yield during milling. In flour, ash content indicates milling performance by indirectly revealing the amount of bran contamination in flour. Ash in flour can impart a darker color to finished products. Products requiring white color call for low ash content, while whole wheat flour has higher ash content.

1000 Kernel Weight is the weight in grams of 1000 kernels of wheat and may indicate grain size and expected milling yield.

Kernel Size is a measure of the percentage by weight of large, medium and small kernels in a sample. Large kernels and more uniform kernel size may help improve milling yield.

Single Kernel Characterization System (SKCS) measures 300 individual kernels from a sample for size (diameter), weight, hardness (based on the force needed to crush) and moisture. Detailed SKCS results (not reported in this booklet) include the distribution of these factors, which may indicate the uniformity of the sample and help millers experienced with the system to optimize flour milling yields. Kernel characteristics may help millers optimize tempering and adjust roll gap settings.

Sedimentation value is a measure of the volume of sediment that results when lactic acid is added to a sifted, ground wheat sample. High sedimentation volume indicates high molecular weight glutenin sub-units (strong gluten) while low sedimentation volume indicates weaker gluten.

Falling Number is the time required for a plunger to fall through a heated mixture of flour and water and is an indirect measure of enzyme activity. Sprouted wheat releases alpha-amylase (α-amylase), which breaks down starch into sugars. High falling number values indicate low α-amylase activity. Some α-amylase is required for certain products such as yeast-raised bread. However, excessive α-amylase in wheat cannot be removed and is difficult to reduce by blending. Flour with excessive amylase activity produces a sticky dough that can cause processing problems and products with poor color, poor crumb grain, and weak texture. Falling number usually correlates closely with amylograph peak viscosity results.

FLOUR AND SEMOLINA DATA

Laboratory Milling Extraction is the percentage by weight of flour obtained from a wheat sample. The extraction rate is always significantly lower from a laboratory mill than the rate than can be obtained on a commercial mill. Lab milling is done mainly to obtain flour for other tests.

Color measures a sample’s lightness (L*) on a scale of 0 to 100 and “chromaticity” or hue on two scales from -60 to +60 for green to red (a*) and blue to yellow (b*). High L* values indicate a bright color and higher b* values indicate more yellow. Flour color is influenced by endosperm color, particle size and ash content and often affects finished product color. Durum semolina color is heavily influenced by particle size.

Wet Gluten is a measure of the quantity of gluten in wheat or flour samples as determined using the Glutomatic System. Wet gluten forms when water is added to the protein in wheat or flour and is responsible for the elasticity and extensibility characteristics of flour dough.

Gluten Index is also determined by the Glutomatic System and is a measure of gluten strength regardless of the quantity of gluten present. Gluten index is used commercially to select durum samples with strong gluten characteristics. In bread (hard)hard and soft wheats, a variety of factors other than gluten quality can affect the results, though very low gluten index may be an indication of protein damage from insect or disease activity.

Amylograph Peak Viscosity measures flour starch pasting properties that are important to products such as sheeted Asian noodles. Amylograph also measures enzyme (α-amylase) activity indirectly, which is usually from sprout damage.

Damaged Starch, the percentage by weight of damaged starch in a flour sample, is a measure percentage of the physical damage done to starch granules during milling. Hard wheat flour typically has higher starch damage than soft wheat flour. Damaged starch granules readily absorb more water, which affects dough mixing and other processing properties. Because starch damage depends on how the sample was milled, starch damage is important for interpreting other reported results.

Solvent Retention Capacity (SRC) is the weight, expressed as percentages, of four solvents held by flour after centrifugation to the original flour weight on a 14% mb. The solvents – deionized water (measuring overall water absorption/control solvent), sucrose (measuring pentosans), lactic acid (glutenins) and sodium carbonate (starch damage) – indicate the ability of flour to absorb water during mixing and either sequester or release water during dough handling. Specific ranges of lower SRC values are desirable for specific soft wheat products, while higher SRC values are desirable for bread products. Gluten performance index (GPI), a calculation of three SRC values – lactic acid/(sodium carbonate + sucrose) – is a good predictor of overall performance of flour in baking applications.

Specks are visually counted in a semolina sample and reported as the number in 16 in2. These small particles of bran or other material that escaped the wheat cleaning and semolina purifying process reflect the milling process and the characteristics of the durum and can detract from pasta appearance and desirability. Sample is pressed under a clear plate and the specks within a 1 in2 marked on the plate are counted. Average of three determinations is expressed as specks per 16 in2.

DOUGH PROPERTY FACTORS

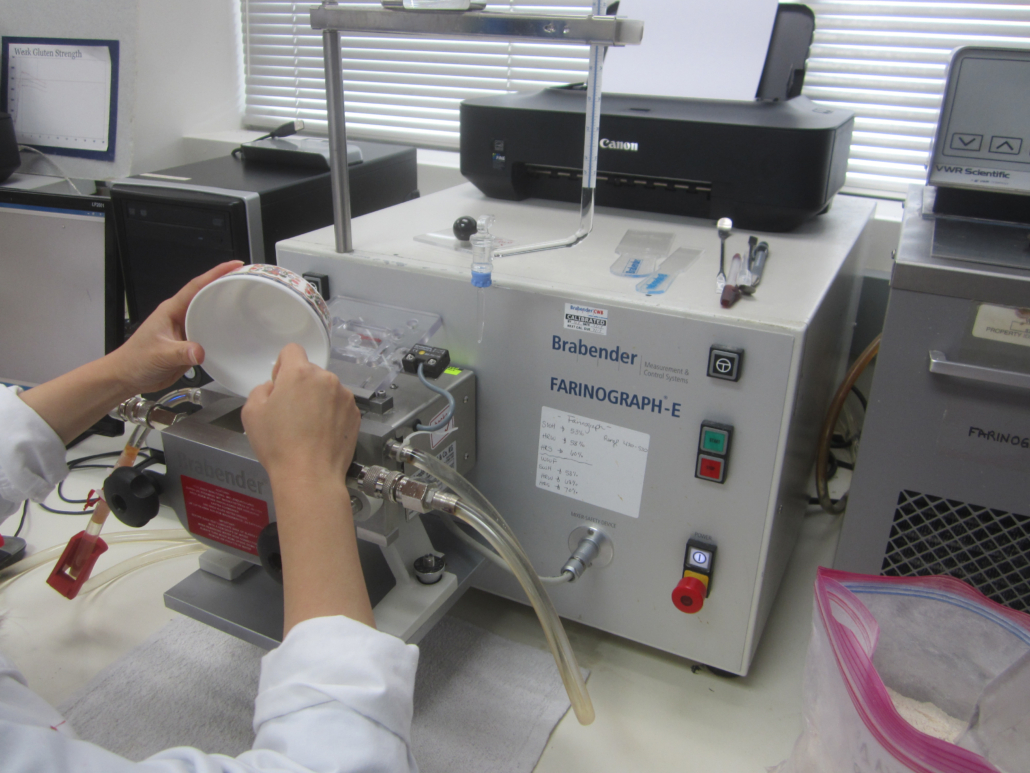

Farinograph generates a curve that indicates the resistance of dough to mixing (the power used over time) as flour and water are mixed into dough. The results describe the mixing properties of the dough and include:

- Peak Time is the time interval from the first addition of water to the maximum curve-center consistency of 500 Brabender Units (BU) immediately prior to the first indication of weakening. Long peak times indicate strong gluten and dough properties while short peak times may indicate weak gluten.

- Stability is the time interval between the point where the top of the curve first intersects the 500BU line (called the “arrival time”) and the point where the top of the curve departs the 500-BU line (“departure time”). Long stability times also indicate strong gluten and dough properties, useful in products such as yeast-raised breads, while short stability times indicate weaker gluten useful in many other products.

- Absorption is the amount of water (as a percent by weight on a 14% mb) required to center the curve peak on the 500-BU line. High water absorption in bread products provides economic advantages by producing more dough pieces with the same amount of flour compared to lower water absorption. Low water absorption is ideal for cookie and cracker products because water has to be baked off for stable finished products.

Alveograph generates a curve indicating the air pressure necessary to inflate a piece of dough like a bubble to the point of rupture and indicates the gluten strength and extensibility of dough. Values reported include:

- P(“overpressure” or resistance), measured in millimeters of water to the maximum height of the curve, reflects the maximum pressure while blowing the bubble of dough and indicates dough resistance to extension.

- L (length), the length of the curve measured in millimeters, reflects the size of the bubble and indicates dough extensibility.

- W(the area under the curve) reflects the amount of energy needed to inflate the dough to the point of rupture and indicates dough strength.

The alveograph is well-suited for measuring the dough characteristics of weaker gluten wheat and, with adapted hydration using a Consistograph, for stronger wheats including durum. Requirements differ depending on intended flour use. Low P values (indicating weak gluten) and short L values (low extensibility) are preferred for cakes and confectionery products; P/L close to 1 and high W values (strong gluten) are preferred for pan breads; and P/L values close to 0.75 are favored for durum for pasta.

Extensograph generates a force-time curve for a piece of dough that is unilaterally stretched until it breaks. Results include:

- Resistance, measured at the maximum curve height in Brabender Units (BU), reflects the maximum force applied and indicates the resistance of the dough to extension.

- Extensibility, measured as the total length of the curve at the baseline in centimeters, reflects how far the dough was stretched.

- Area is the area under the curve reported in cm2.

These factors help describe the gluten strength and dough extensibility characteristics of flour for a wide range of end-products. The extensograph can also evaluate the effects of fermentation time and additives on dough performance.

END PRODUCT EVALUATIONS

BREAD

Baking Absorption is the water required for optimum dough mixing performance, expressed as a percent of flour weight on a 14% mb.

Crumb Grain and Texture is determined on a scale of 1 to 10 by visual comparison to a standard using a constant illumination source. Higher scores are preferred.

Loaf Volume is the volume of a test loaf after baking. Higher loaf volumes indicate better baking performance for pan breads.

COOKIES (BISCUITS)

Cookie Diameter is a function of spread rate and set time during baking and is an indicator of good pastry-making and specifically cookie-baking potential. Larger diameter is preferred.

Cookie Spread Factor is width (W) and thickness (T), ratio with adjustments to constant atmospheric pressure and conditions. Values over 9 are preferred, over 10 are ideal.

NOODLES, CHINESE

Noodle texture is determined on five strands of cooked noodles with a strand cross-cut dimension of 2.5 x 1.2 mm for raw noodles, W x T (Width x Thickness); 1.7 x 1.7 mm for wet noodles (Wheat Marketing Center (WMC) procedures), W x T using a Stable Micro Systems TA.XTPlus Texture Analyzer.

Firmness indicates noodle bite.

Springiness indicates the degree of recovery after first bite.

Cohesiveness is a measure of noodle structure disruption during first bite.

Chewiness is a product of firmness, cohesiveness and springiness (firmness x cohesiveness x springiness) and thus is a single parameter that incorporates the three textural parameters. Higher textural parameter values are generally more desirable for Chinese-style noodles.

Sensory Noodle Color Stability Score is a total score of noodle color rated at 2 and 24 hours against a control sample (an assigned score of 7) and is reported based on a 1 to 10 scale; higher scores indicate better color stability.

SPAGHETTI

Color Score is based on the relative brightness and yellowness of spaghetti as measured by a reflectance colorimeter as described by AACC 14-22.01. Higher values (scale 1-12) are preferred. Color scores are determined by the procedure described by Walsh, Macaroni Journal 52: (4) 20 (1970), using a Minolta Color Difference Meter (Northern CR-410, Desert Durum® CR-210).

Cooked Weight is best used in conjunction with firmness values to determine the cooking qualities of a spaghetti sample; high weight and high firmness values indicate high quality while high weight and low firmness indicate poor quality.

Cooking Loss is a measure of the amount of solubles that leach from pasta during cooking.

Firmness is a measure of the amount of work required to bite through a strand of spaghetti.

SPONGE CAKE

Volume is measured by Tex-Vol Volumeter. Large volume indicates better flour.

Texture Score: Each cake is measured by TA-XT Plus texture analyzer for softness and compared to the control. The maximum score is 30 and the control is set at 70%, which is 21.

External Score: Each cake is subjectively evaluated against the control. The maximum score is 20 and the control is set at 70%, which is 14.

Internal Score: Each cake is subjectively evaluated against the control. The maximum score is 30 and the control is set at 70%, which is 21.

Total Score comprises texture, external factors, and internal factors. The control flour is scored 56; maximum score is 80

STEAMED BREAD

Specific Volume is defined as the ratio of volume in milliliters to the weight in grams. Larger specific volume is usually preferred.

Total Score comprises volume*, external characteristics, internal characteristics, eating quality and flavor. Each property is rated compared with a control sample. The control flour is scored 70.