This article on wheat digestibility is reprinted with permission from Prairie Grains and written by the Agricultural Utilization Research Institute (AURI). Additional thanks to the Minnesota Wheat Research and Promotion Council, a member of U.S. Wheat Associates (USW).

In past issues of Prairie Grains Magazine, [AURI has] highlighted ongoing research investigating ways to reduce potentially reactive components of wheat, like FODMAPs and ATIs. FODMAPs are sugars, known as fermentable oligosaccharides, disaccharides, monosaccharides and polyols. ATIs are proteins called amylase-trypsin inhibitors. Research indicates that “anti-nutrients,” such as ATIs, and fructans (a component of FODMAPs) in wheat have been identified as triggers of irritable bowel syndrome (IBS).

Not By Gluten Alone

There is a growing understanding that wheat digestibility issues may not be solely caused by gluten sensitivity but are also related to the presence of FODMAPs and ATIs. According to Dr. George Annor, assistant professor of cereal chemistry and technology at the University of Minnesota, FODMAPs are normally present in small quantities and tolerated by most.

However, foods with more than 0.3 grams per serving (the equivalent of two slices or more of bread) … can cause issues. FODMAPs are best tolerated if less than 0.3 grams per serving.

For individuals with this sensitivity, changes to wheat characteristics or processing techniques can result in more digestible products, increasing quality of life for consumers and allowing them to enjoy the health benefits of wheat products.

There is a growing understanding that wheat digestibility issues may not be solely caused by gluten sensitivity but are also related to the presence of FODMAPs and ATIs.

Conducted through a partnership between the Minnesota Wheat Research and Promotion Council (MWRPC), the Agricultural Utilization Research Institute (AURI), the University of Minnesota’s College of Food, Agricultural and Natural Resource Sciences (CFANS) and its Regional Sustainable Development Partnership, as well as Back When Foods, Inc., this research has the potential to create new products and processes that will positively impact the entire wheat industry value chain.

The hypothesis set for this research is that ATIs and FODMAPS can be reduced through breeding programs and processing techniques (i.e. sourdough fermentation) of modern, heritage and ancient wheat. The reason this topic is important to wheat growers and the entire industry is researchers’ belief these reactive components are triggers of non-celiac gluten sensitivity and irritable bowel syndrome (IBS), which cause many people to avoid wheat-based products. Instead, they look for less-reactive products, thus reducing the overall consumption of wheat-based products impacting the industry overall. Until now.

The MWRPC and its partners undertook this endeavor in order to create new opportunities for wheat-based products, consumable by those with wheat digestion concerns. Additionally, the study has the potential to provide new market opportunities that could have a positive financial impact for growers, the wheat industry and Minnesota.

Research suggests that wheat breeding has not increased FODMAP nor ATI levels in modern wheat varieties.

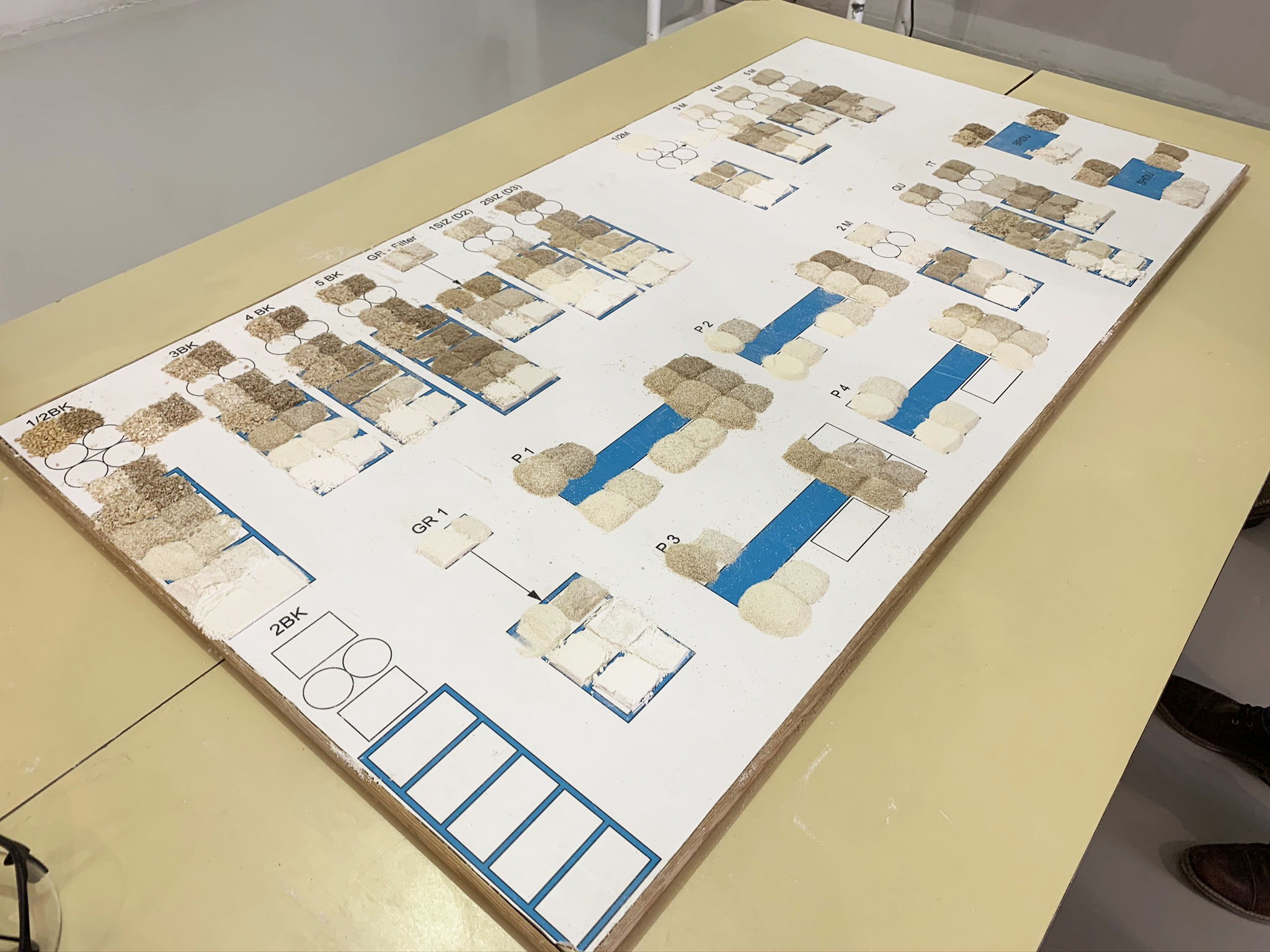

“We have identified significant variation in FODMAP and ATI levels in a diverse panel of wheat varieties, including among modern wheat germplasm,” said Dr. James Anderson, professor of wheat breeding and genetics at the U of M. “This variation may allow us to selectively breed for lower levels of these anti-nutrients. The ancient Einkorn and Emmer wheats were consistently low in FODMAPs, and Einkorn was also low in ATIs.”

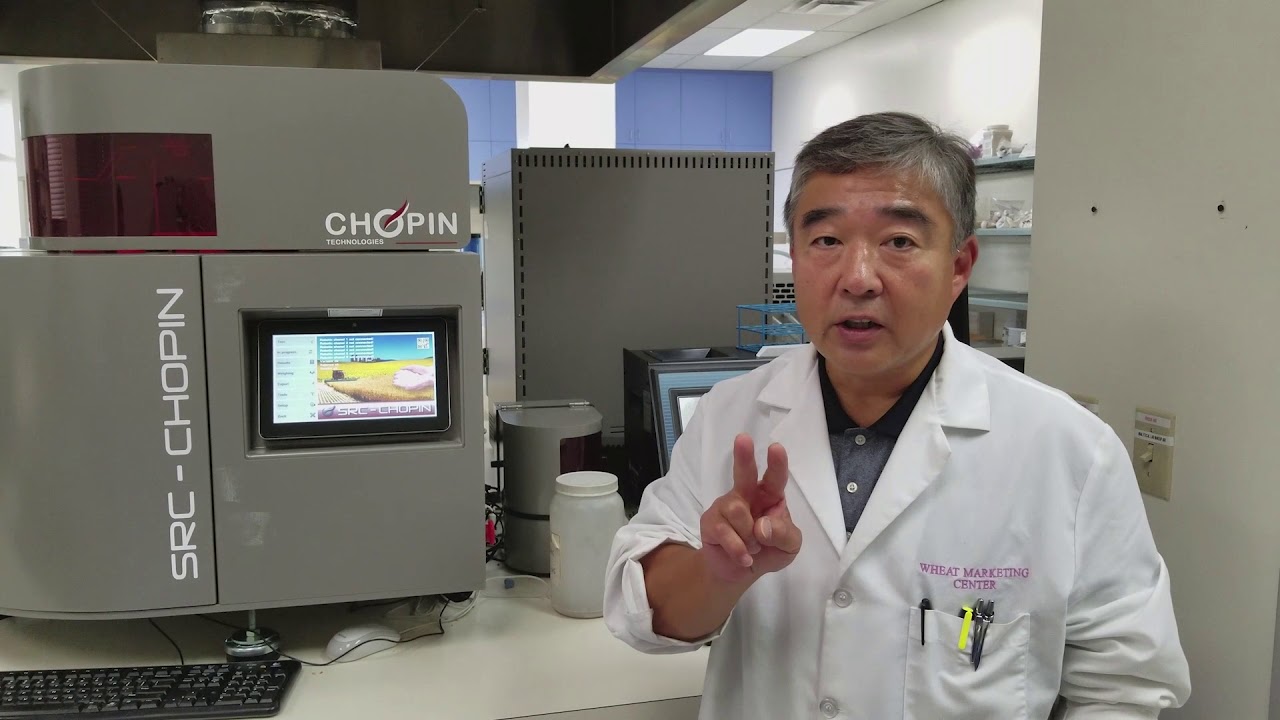

Annor said research shows that sourdough production can help reduce the amount of FODMAPS and ATIs in wheat.

“Screening the ancient, heritage and modern wheat varieties for their FODMAPs and ATI gave us important insights into how these parameters vary in different wheat varieties,” Annor said. “It was apparent that we have not inherently bred them for increased levels of FODMAPs and ATI over the years. Our study also showed that fermentation was very effective in reducing FODMAPs and ATI levels in wheat in the form of sourdough. These results tell us that sourdough production can be effectively used to reduce the levels of FODMAPs and ATIs in wheat.”

New Approaches

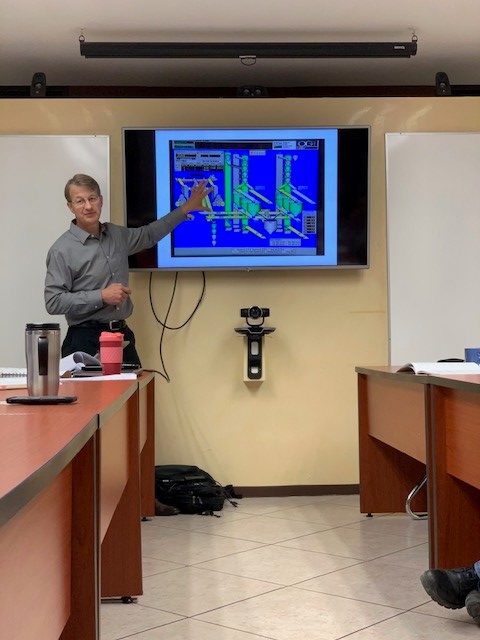

Coupled with breeding efforts to reduce the levels of anti-nutrients in wheat lines, the degradation of FODMAPs and ATIs through sourdough fermentation provides immediate opportunities for wheat growers to regain market share by focusing their efforts on channeling their crops directly to the ever-growing artisan bakery sector. An additional channel for growers to use the research findings is in support of ongoing breeding programs and low FODMAP certification, in which large-scale processors have shown great interest.

“Both FODMAP and ATI levels appear to be under complex genetic control,” Anderson said, “thus making the selective breeding of these traits more difficult. But I’m optimistic that we can make breeding progress.” Anderson added that new approaches involving DNA sequencing and genomic prediction will be used to enhance our breeding efforts to reduce FODMAP and ATI levels.

As the project researchers and partners continue to seek ways to have a meaningful impact on the wheat industry overall, plans are underway to continue to build upon these recent findings in a second phase that focuses on further development of wheat varieties that not only have improved digestibility but also have high amylose and resistant starch content for a lower glycemic index and improved gut health (microbiome).

Financial support for this project is provided by an Agricultural Growth, Research, & Innovation Crop Research Grant from the Minnesota Department of Agriculture. The AGRI program awards grants, scholarships and cost shares to advance Minnesota’s agricultural and renewable energy industries.

For more information about the AGRI program, visit www.mda.state.mn.us/grants/agri. To learn more about AGRI Crop Research Grants, visit www.mda.state.mn.us/cropresearch. For more information, and to follow this research, visit www.auri.org/agri.