Global demand for wheat food grows stronger every year, making exports vital to U.S. wheat farmers. As the export market development organization for the U.S. wheat industry, U.S. Wheat Associates (USW) works to help wheat buyers, millers, bakers, wheat food processors, and government officials understand the quality, value, and reliability of all six U.S. wheat classes. USW relies on its successful working relationships with world-class educational partners that, through courses, workshops, and seminars, enhance the technical and trade service assistance to help distinguish U.S. wheat from its competitors. One of those partners is the International Grains Program Institute (IGP) in Manhattan, Kan.

Located in the Kansas State University (KSU) Grain Science Complex, the IGP Institute offers innovative technical training courses and workshops to enhance market preference, consumption, and utilization of U.S. cereal grains and oilseeds and their value-added products. On-campus, on-location, and virtual education courses are led by KSU faculty and industry professionals in the areas of flour milling and grain processing, grain marketing and risk management, and feed manufacturing and grain quality management.

Adding Value

IGP’s mission is to demonstrate that U.S. grains offer a competitive advantage over other suppliers, especially regarding quality and consistency. IGP is focused on providing technical leadership in milling, baking, and grain storage for the wheat industry.

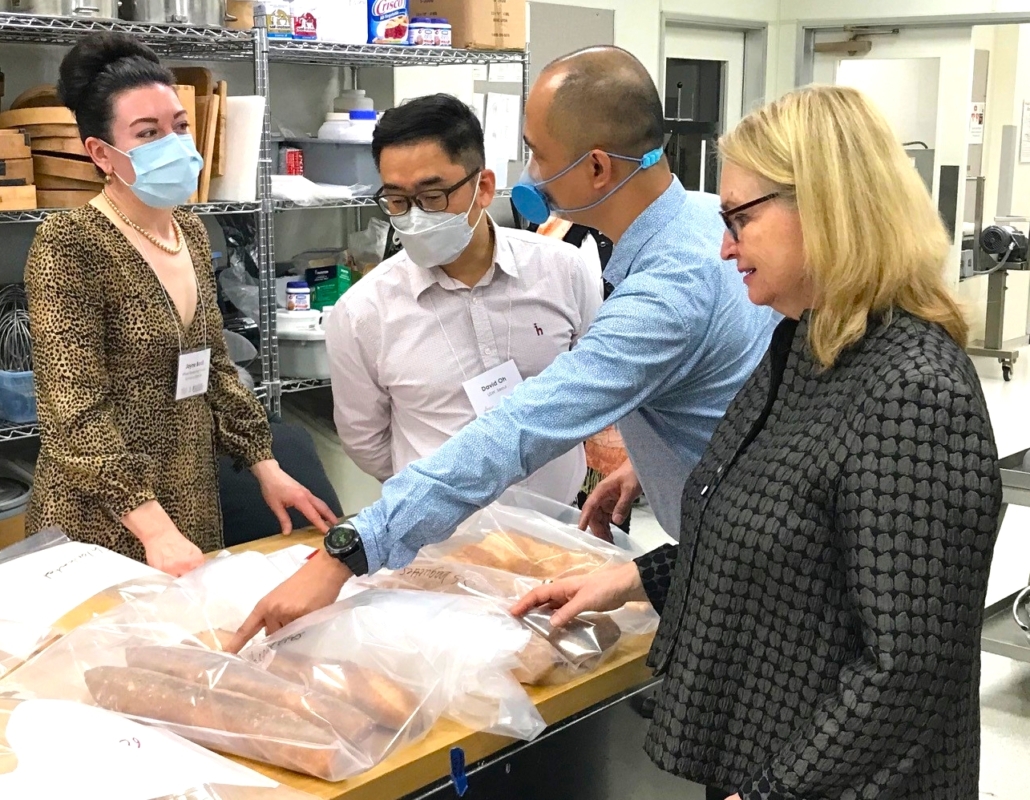

Shawn Thiele, IGP Associate Director and Flour Milling and Grain Processing Curriculum Manager, says that hands-on training is where participants maximize their experience, which is why IGP prioritizes scheduling a majority of course time for hands-on training or field visits outside of the classroom. IGP partners with the International Association of Operative Millers (IAOM) and Buhler to host many of the grain processing and flour milling courses that focus on everything wheat and milling related, from wheat selection and storage, flour blending and quality control to end-use products and mill optimization and maintenance.

“We have a range of courses from an introduction to flour milling, which is geared towards non-millers working in the milling industry, to basic and advanced milling courses,” said Thiele. “Our goal is to showcase the importance of wheat quality and train participants on how to optimize the milling process to maximize extraction and quality of the U.S. wheat. Through each of these courses, we discuss all six classes of U.S. wheat, how their different characteristics translate into different milling practices, and how to optimize each to extract its full value and quality.”

In its grain marketing curriculum, led by Guy H. Allen, Senior Agricultural Economist and Grain Marketing and Risk Management Curriculum Manager, IGP offers courses beneficial for commodity traders, bankers, and individuals responsible for buying U.S. food and feed grains. The grain procurement and purchasing course focuses on the mechanics of purchasing raw materials and features detailed discussions of cash and futures markets, contracts, and ocean transportation. The risk management course focuses on the principles of risk management and commodity price control through hedging principles and using various hedging strategies. Allen is also working on new educational opportunities featuring grain supply chain field trips throughout the United States and applied agricultural sales training focused on professional sales and marketing for agriculture and related industries.

IGP also provides training on proper grain storage and handling techniques taught by Carlos Campabadal, Feed Manufacturing and Grain Quality Management Curriculum Manager and Spanish Outreach Coordinator. Campabadal has extensive international feed manufacturing experience and travels worldwide, providing assistance and education for grain handling, storage, and feed manufacturing challenges in developing countries.

State-of-the-Art Facilities

The IGP Institute Conference Center offers multiple technology-enabled classrooms, dining facilities, a grain grading lab that meets USDA standards, and a large auditorium featuring simultaneous language translation capabilities. The complex is also home to the commercial-scale Hal Ross Flour Mill, O.H. Kruse Feed Technology and Innovation Center, the Bio-processing and Industrial Value-Added Products (BIAVP) Innovation Center, and laboratories for flour and dough testing and baking. As part of the KSU Department of Grain Science and Industry, the IGP Institute leverages the department’s unique diversity of resources.

“To meet our mission, we have many value-added tools and multi-disciplinary faculty to aid our focus on technical assistance, including millers, bakers, feed scientists, food scientists, grain storage specialists, and economists,” said Thiele. “We also utilize resources from the industry, as needed, to ensure top experts are teaching the respective material.”

Located in the heart of hard red winter (HRW) wheat country, IGP’s proximity to the Kansas Wheat Innovation Center, wheat farmers, grain elevators, commercial flour and feed mills, commercial bakeries, USDA-ARS, and the Federal Grain Inspection Service all allow course participants to experience and learn from the full spectrum of the wheat supply chain.

Thiele adds that IGP’s partnerships help make its programming successful.

“U.S. Wheat Associates, the Kansas Wheat Commission, and other supporting commodity organizations are critical to what we do,” said Thiele. “In addition to financial support, the value of our relationship with industry partners and the donation of their time and materials is difficult to quantify.”

Every year, USW sponsors international customers to attend IGP courses focused on grain purchasing and flour milling. In 2022, IGP hosted USW technical staff for a core competency training session and is planning on hosting a USW advanced flour milling course for South Korean millers utilizing U.S. wheat.

Technical Training. USW technical staff visited the IGP Institute in March 2022 for a core competency training session.

“IGP provides a good learning environment and experienced instructors that help millers lay a solid foundation for milling U.S. wheat,” said Boyuan Chen, USW Country Director for Taiwan.

Past course participants agree.

“The program helped us improve our flour milling operations,” said Vangala Ravindra from Pure Flour Mills in Nigeria. “We understand the different U.S. wheat variety characteristics, their end-uses, and impact on milling extraction and flour quality.”

Nestor Morales, from Gold Mills in Panama, attended an IGP grain purchasing course last month and is already beginning to implement what he learned.

“The staff at IGP was phenomenal. I now have a very good impression of the quality assurance that exists in the entire U.S. wheat value chain,” said Morales. “This course has the potential of improving our buying practices and better understanding the market in greater detail.”

IGP continues to look for ways to better reach U.S. wheat customers by working with industry partners and educational resources to expand on virtual and on-location training options. Recently, IGP has expanded its curriculum by adding new courses focused on the science of baking. These feature hands-on training and are taught by grain science department faculty with years of commercial baking industry experience.

Thiele said that IGP is expanding those opportunities by using innovative and engaging virtual learning platforms to record key topics that are typically only offered on-site. These new training lectures and courses will build on IGP’s virtual and on-demand training options.

“Our goal is that these tools are the first step toward customers saying, ‘wow, this is something that I need to invest more in,'” said Thiele. “At the end of the day, the biggest benefit is being in person at IGP to get the full experience and build long-lasting relationships. Nothing can replace that face-to-face interaction.”

Learn more about the IGP Institute and its programming and services at https://www.grains.k-state.edu/igp/.

By Amanda J. Spoo, USW Director of Communications

Read about other USW educational partners in this series:

Northern Crops Institute Continues Tradition of Adding Value to U.S. Spring Wheat and Durum

Wheat Marketing Center Creates Educational Bridge Between U.S. Wheat Farmers And Customers

Wheat Foods Council Is A Leading Source Of Science-Based Wheat Foods Information

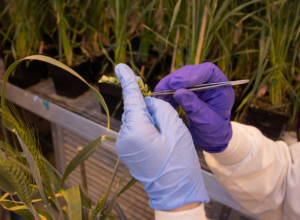

From uncovering the dense nutrients for improving wheat as a food crop to bringing in trails from wheat’s wild relatives or improving agronomic traits, Gallagher told Harries there is still more to unlock in the wheat genome.

From uncovering the dense nutrients for improving wheat as a food crop to bringing in trails from wheat’s wild relatives or improving agronomic traits, Gallagher told Harries there is still more to unlock in the wheat genome.