A recently released econometric study confirmed that two export market development programs administered by the USDA Foreign Agricultural Service (FAS) benefit wheat farmers, their overseas customers and the general U.S. economy.

“Four studies since 2007 using various econometric models have all shown the same bottom line result – export market development programs work for American agricultural producers,” said Robbie Minnich, Chair of the Coalition to Promote U.S. Agricultural Exports and Senior Government Relations Representative with the National Cotton Council. “Without question, the economic benefits they return far exceed the investment made.”

Learn more about USDA export market development here.

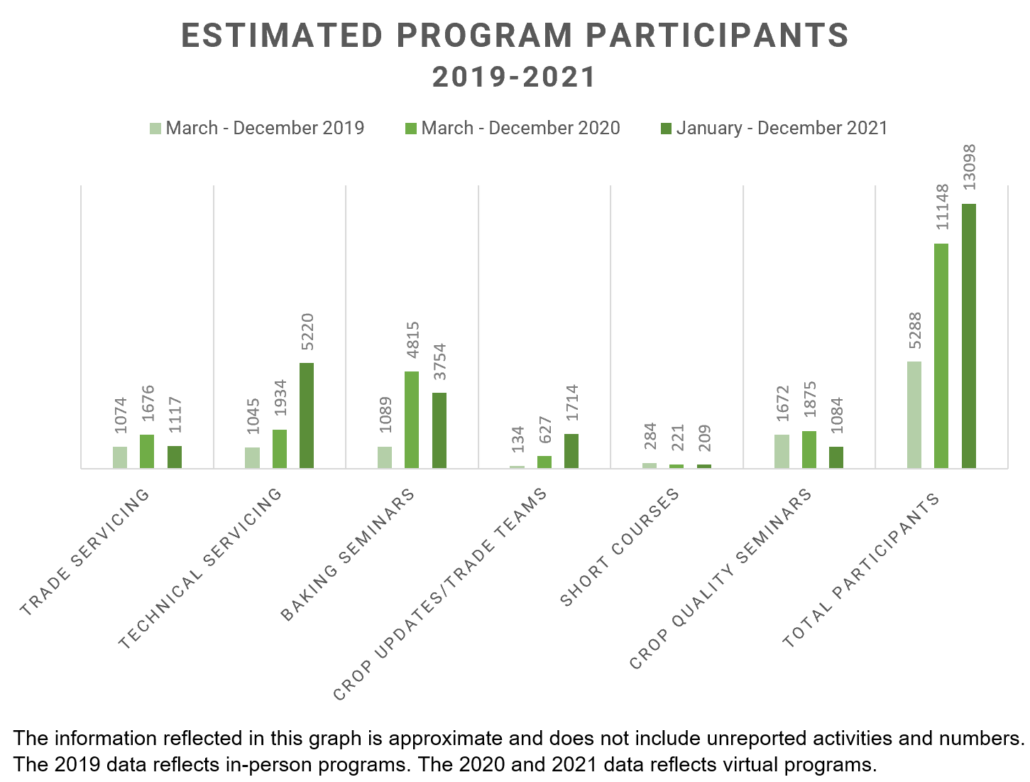

U.S. Wheat Associates (USW) participates in the Market Access Program (MAP) and the Foreign Market Development (FMD) program on an annual basis. These programs are apportioned by law in the U.S. federal budget. They are public-private partnerships between USDA and organizations like USW and 17 state wheat commission members that help fund its activities. Across all the participating organizations, private contributions to the programs represented more than 70% of total funding in recent years.

Wheat Trade

Wheat is the most trade-dependent of the major food and feed crops grown in the United States. But individual farming operations cannot effectively market wheat overseas. The MAP and FMD programs help to encourage those customers to consider the various classes and qualities of U.S. wheat.

With funding from MAP, FMD and U.S. wheat farm families, experienced USW staff and consultants add exceptional value to all U.S. wheat class imports. USW also invests substantial funding to help overcome trade or technical barriers that would otherwise keep end-users from realizing the highest value and most revenue from using U.S. wheat.

“These export market development programs enable U.S. Wheat Associates to build a critical reserve of trust and goodwill with our overseas buyers, end-users and influential government officials, as well as key U.S. government agencies and officials,” said USW President Vince Peterson. “And there is a clear return on investment—for every dollar spent on export promotion, there is a return of $24.50 in additional net export revenue – and the return is even higher to the U.S. wheat supply system.”

U.S. Farm and Economic Returns

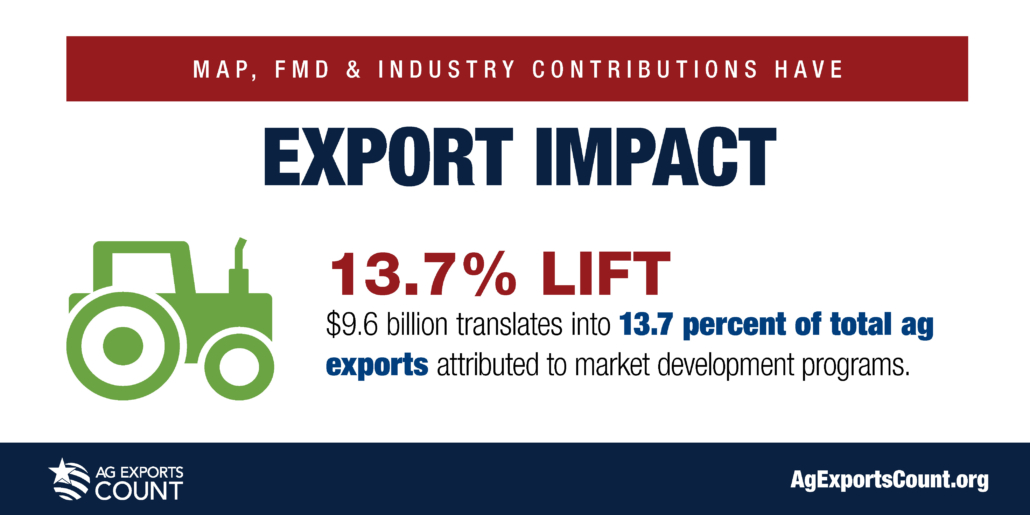

The new econometric study, conducted by IHS Markit and Texas A&M University agricultural economists Dr. Gary Williams and Dr. Oral Capps, showed export programs added an average of $9.6 billion per year to export value between 1977 and 2019. For farmers, livestock producers and dairy operators, the study showed MAP and FMD increased cash receipts by $12.2 billion per year. The study also indicated that these export market development programs added 225,800 new jobs across the entire U.S. economy.

“Our work indicated that MAP and FMD have accounted for 13.7% of all the revenue generated by U.S. agricultural exports between 1977 and 2019,” said Dr. Williams. “The additional export revenue bolsters the entire U.S agricultural sector and creates a multiplier effect throughout the U.S. economy.”

Export Market Development programs fund the trade and technical service that adds value to U.S. wheat imports and dozens of other U.S. agricultural export products.

The Coalition to Promote U.S. Agricultural Exports welcomed the results of the study. In letters sent on April 27, 2022, members of the Coalition, including USW and other organizations, asked U.S. House and Senate agricultural appropriations subcommittee leadership to maintain funding of at least $200 million for the Market Access Program (MAP) and $34.5 million for the Foreign Market Development (FMD) program in FY2023.

ATP Investment Also Analyzed

The study also analyzed the potential impact of the Agricultural Trade Promotion (ATP) program that the USDA established in 2019.

The ATP program provided $300 million to cooperating organizations, to which they contributed $90 million in cash, goods and services. The study’s analysis of future expected returns from those investments between 2019 and 2026 predicts that incremental funding for agricultural export market development will provide an excellent return.

The full export market development study, the Coalition letters to congressional appropriators, and more information about the value of U.S. agricultural exports to U.S. producers and their global customers are available at www.AgExportsCount.org.